Mon - Fri: 9:00 - 19:00

Mon - Fri: 9:00 - 19:00

In January 2025, as the Chinese Spring Festival approached, the busy atmosphere of bidding farewell to the old and welcoming the new was in full swing. At this time, Sales J received an email from Brazil in his inbox—the sender was a long-term ...

In January 2025, as the Chinese Spring Festival approached, the busy atmosphere of bidding farewell to the old and welcoming the new was in full swing. At this time, Sales J received an email from Brazil in his inbox—the sender was a long-term client with whom we had maintained in-depth cooperation for three years. Specializing in the commercial vehicle sector in Brazil, this enterprise not only focuses on the maintenance services of logistics vehicles but also engages in related production businesses. Its procurement manager holds unique insights into the industry. What seemed like a routine business communication email turned out to be a brand-new starting point for CISBO to deeply integrate AI algorithms with blind spot detection technology.

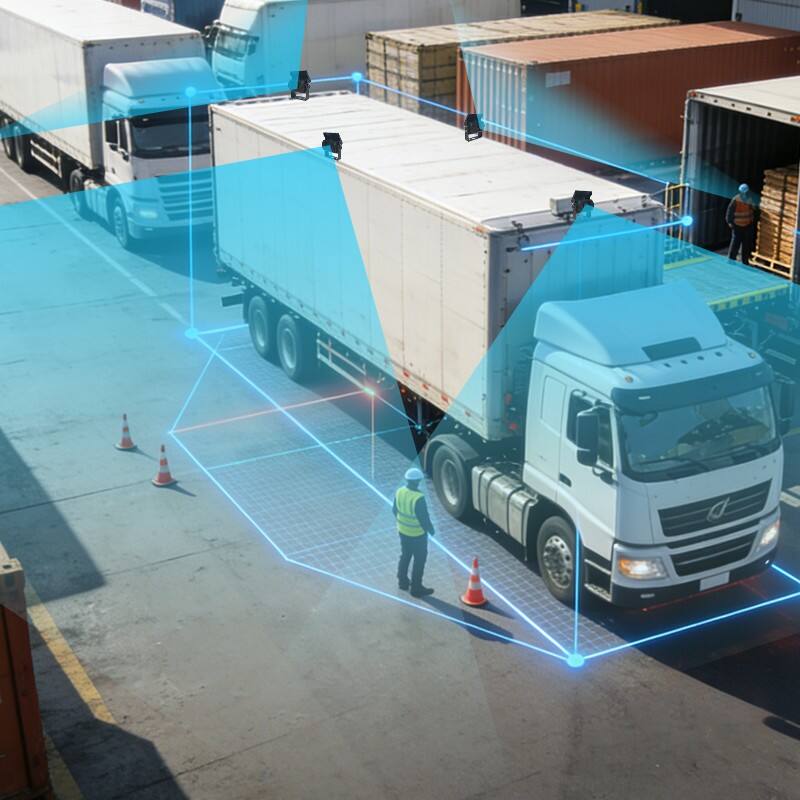

Sales J carefully studied the content of the email at the first opportunity and promptly got in touch with the Brazilian client via phone. Through in-depth communication, we clearly understood the tough predicament the client was facing. As a core hub in Brazil's supply chain system, the client's logistics vehicles had to travel year-round between long-haul trunk lines, urban distribution outlets, and large-scale logistics parks, operating in complex and ever-changing scenarios. Coupled with multiple factors such as weak road infrastructure and rugged road conditions in some local areas, driver fatigue during long-distance driving, dense pedestrian flow on urban roads, frequent cross-operation of vehicles in parks, and insufficient light for nighttime transportation, safety issues such as blind spot collision risks during high-speed lane changes, scratch accidents during operations in parks, and visual interference during nighttime driving occurred frequently. These potential safety hazards not only directly threatened the lives of drivers and increased vehicle maintenance costs but also easily caused delays in logistics transportation, affecting the operational efficiency of the upstream and downstream of the supply chain, and thus became a key bottleneck restricting the expansion of the client's business.

|

|

|

Potential Safety Hazards of Logistics Vehicles

Core Advantages of CISBO C98AI-407

Upon gaining insight into customer needs, the CISBO R&D team immediately launched the development of a customized AI 360° Blind Spot Detection System for the Brazilian market. To adapt to the "long-haul trunk line + urban distribution" operational characteristics of local logistics vehicles, the R&D team conducted in-depth research on Brazil's road conditions, high-temperature and high-humidity climate, and logistics operation models, accumulating a vast amount of first-hand data. They adjusted parameters day and night and labeled a large number of local road condition images. During scenario simulation tests, hundreds of repeated tests were carried out for different scenarios such as rainstorms and long-distance driving. Ultimately, the customized C98AI-407 system was successfully launched three months later, building a dual guarantee of safety and efficiency for Brazil's logistics and transportation industry.

Impressive Results

Beyond the impressive performance metrics, the product’s stable operation has earned unanimous recognition from Brazilian clients, spanning from management to drivers.The Brazilian procurement manager spoke highly of it at the project review meeting: “The implementation of CISBO’s customized AI 360° Blind Spot Detection System has completely resolved the safety pain points in our long-haul trunk line and urban distribution operations. It is the core guarantee for the success of this logistics upgrade project!” Drivers also echoed their approval: “Previously, we were always on edge about blind spot risks when navigating the complex road conditions around São Paulo’s congested streets. Now we feel much more at ease behind the wheel!”

With over 20 years of experience in the on-board vision field, CISBO is committed to developing a multi-dimensional fusion system of vision + audio + radar to achieve full-range perception of static obstacles and dynamic vehicles, providing integrated people-vehicle-cargo safety guarantees. For more product details or solutions, please contact the CISBO official team.